- Laser Beam Delivery

- Custom Laser Systems

- Custom Machining

- Laser Delivery Optics

- Laser Beam Diagnostics

- Merged Technologies

- Events

- About Us

- Technical Center

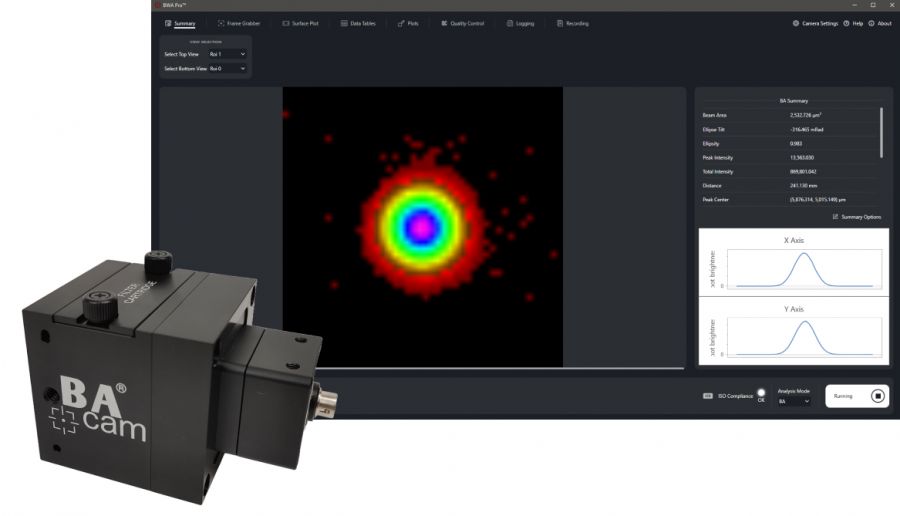

The most modular laser profiler cameraThe BA-CAM® Laser Beam Analyzer Camera is a compact, advanced, ISO 13694 compliant profiler, enabling easy measurement of laser beam characteristics such as spatial intensity, ellipticity, and size, with high attenuation and adaptability for various wavelengths and power levels up to 30KW. Learn more about our profiler camera product line |

|

|

|

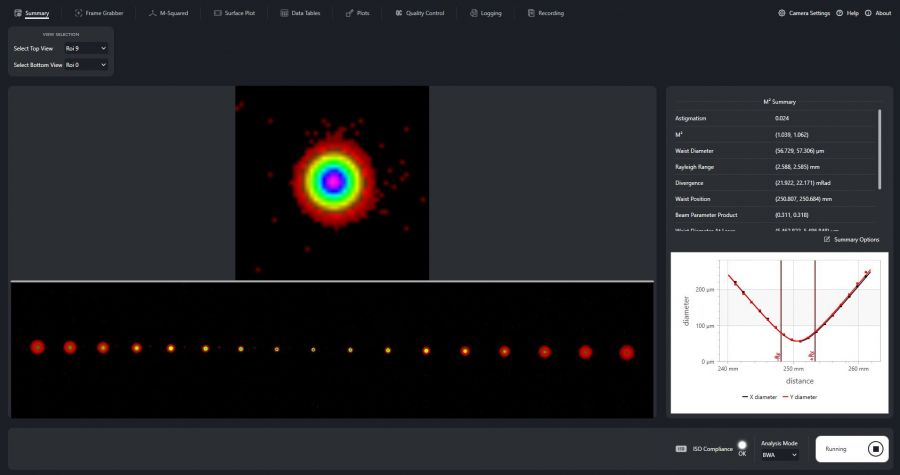

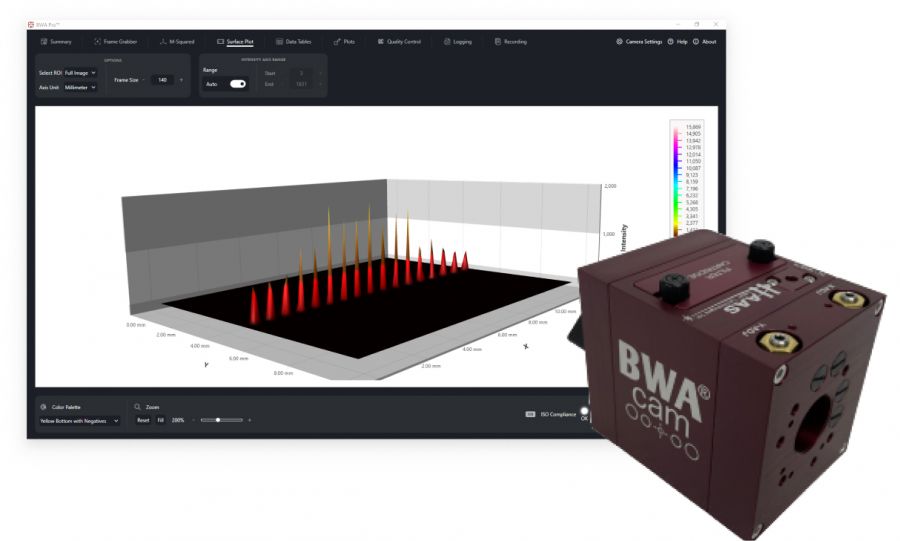

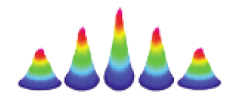

Fastest and most repeatable laser beam waist analyzer toolThe BWA-CAM® Laser Beam Analyzer Camera is a compact, ISO 11146 and ISO 13694 compliant analyzer, enabling easy measurement of laser beam characteristics such as M2, BPP and Rayleigh range with high attenuation and adaptability for various wavelengths and power levels up to 30KW. Learn more about the beam waist analyzer product line |

Patented Technology Overview |

||

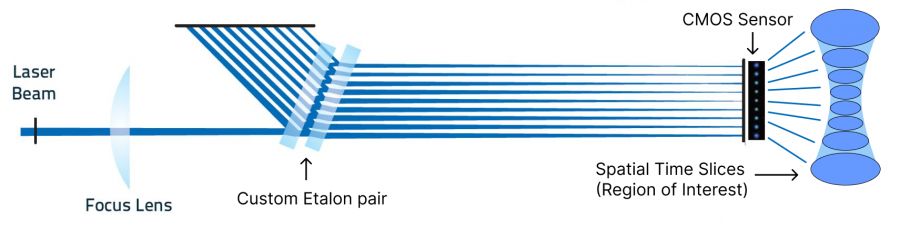

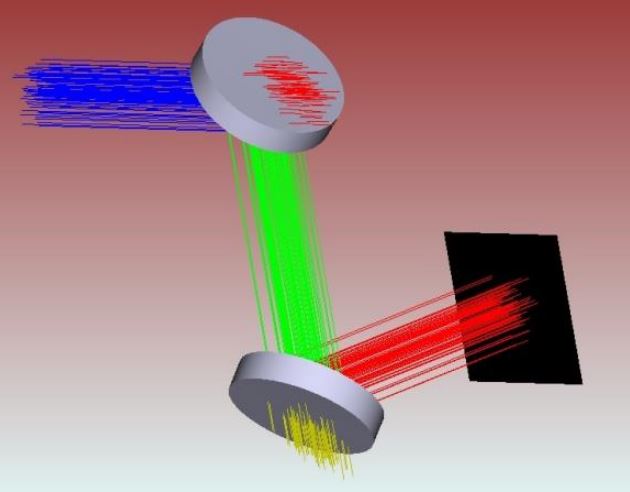

Measuring the beam profile using Spatial Time SlicesThe BWA-CAM utilizes a unique method to analyze the laser beam by creating spatial time slices. This is achieved without the need for any moving mechanical parts, which is a significant advancement over traditional beam analysis methods that require mechanically moving scanning components along the beam caustic. |

||

|

|

||

Real Time M-Squared MeasurementsThe spatial time slices generated by the custom etalon pair are captured by a high-speed CMOS sensor, which has been adapted by removing the window to eliminate any interference effects. This sensor setup enables the BWA-CAM to provide rapid feedback on the beam's properties, facilitating real-time analysis. |

||

|

The BWA-CAM represents a significant leap in laser beam analysis technology. By employing a pair of custom etalons to create spatial time slices of the focused beam, this patented analyzer eliminates the need for moving parts, thereby enhancing reliability and enabling real-time, accurate M-square measurements at the frame rate of the camera or in a single laser pulse. This approach not only simplifies the process of laser beam analysis but also provides critical insights into the beam's properties with unprecedented speed and precision, essential for optimizing laser applications in various industrial settings. |

"Methods to measure laser beam metrics from low power to 30 kilowatts with full ISO 11146-1 compliance in real time"Discover how Haas Laser Technologies has revolutionized laser beam profiling with a groundbreaking approach, resulting in a system that surpasses previous benchmarks in speed, accuracy, and compactness. This white paper delves into:

|

|

||

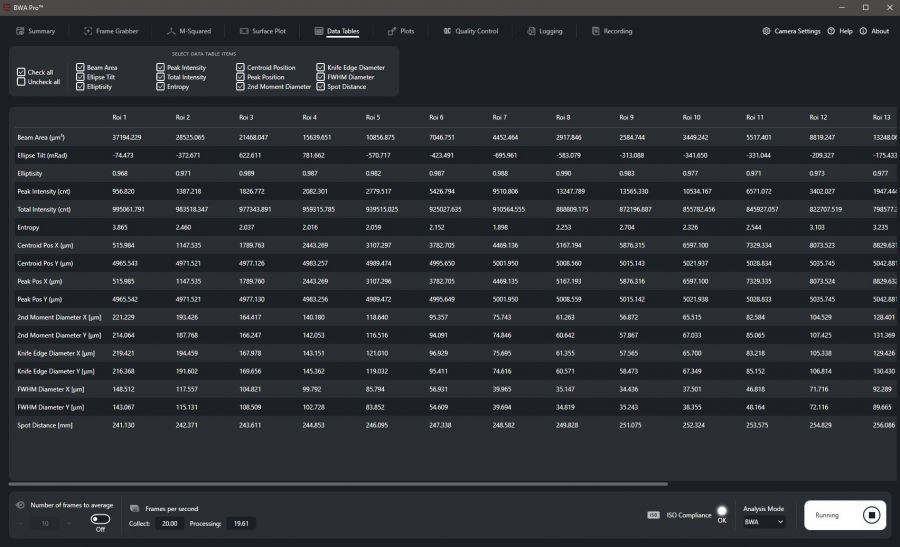

Enterprise Level Software

All cameras include the BWA-PRO software used to operate and record data from either the BA-CAM or BWA-CAM.

Click the button below to learn more about the BWA-PRO software all its features.

Robust Data Export options |

Auto generated 2D and 3D Beam Profile Plots |

SDK Available |

||

| Export beam characteristics and quality reports in multiple formats for easy collaboration | View the full Rayleigh Range in both 2D and 3D along with high resolution plots of the beam profile | Use our SDK to incorporate our BWA-Pro software into a number of different applications |

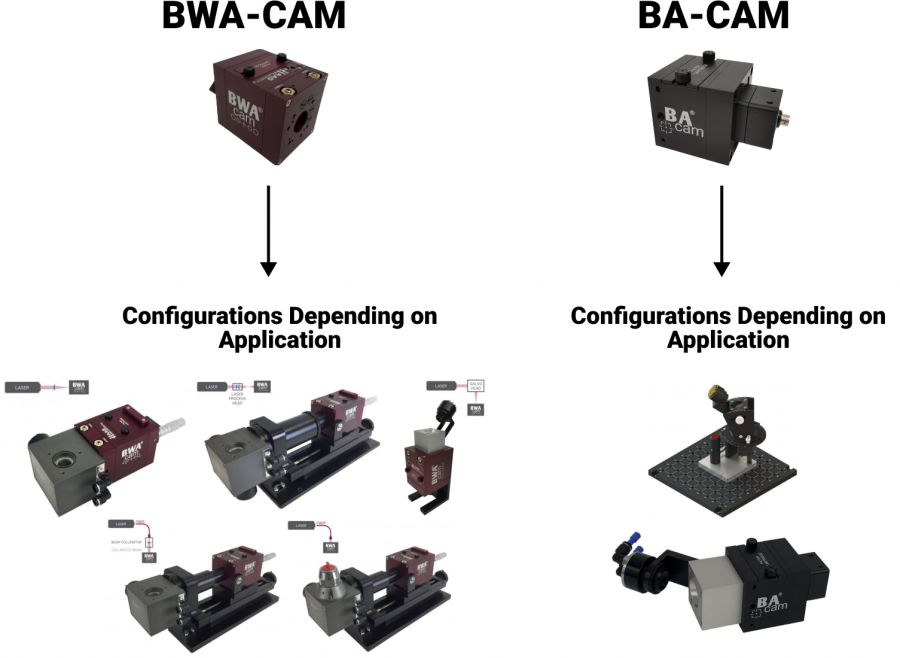

Module design for any applicationEngineered for versatility, our system's modular design meets the specific needs of laser analysis across various applications. Tailored to accommodate diverse laser setups and operational demands, it emphasizes precision and adaptability. This approach enables accurate measurements of laser beam characteristics, ensuring compatibility with a broad spectrum of wavelengths and power levels. Equipped for real-time 2D and 3D laser beam diagnostics, it adheres to the rigorous ISO 11146 and ISO 13694 standards for comprehensive spatial metrics analysis. Ideal for engineers, researchers, and scientists seeking customizable laser diagnostic solutions, it offers unmatched flexibility in optimizing laser performance for research, industrial applications, and quality assurance initiatives. Custom configurations can be developed upon request |

|

Realtime M2 Measurement and Full Rayleigh Range AnalysisOur system transforms laser beam diagnostics with its cutting-edge capabilities, designed for real-time precision and comprehensive analysis:

|

|

Versatile Power Range Support with Built-In AttenuationEngineered for adaptability across a wide range of laser power levels, our system integrates sophisticated features to ensure precision and efficiency:

This comprehensive approach to power range support underscores our commitment to delivering adaptable, precise solutions for laser diagnostics across all levels of industry and research. |

|

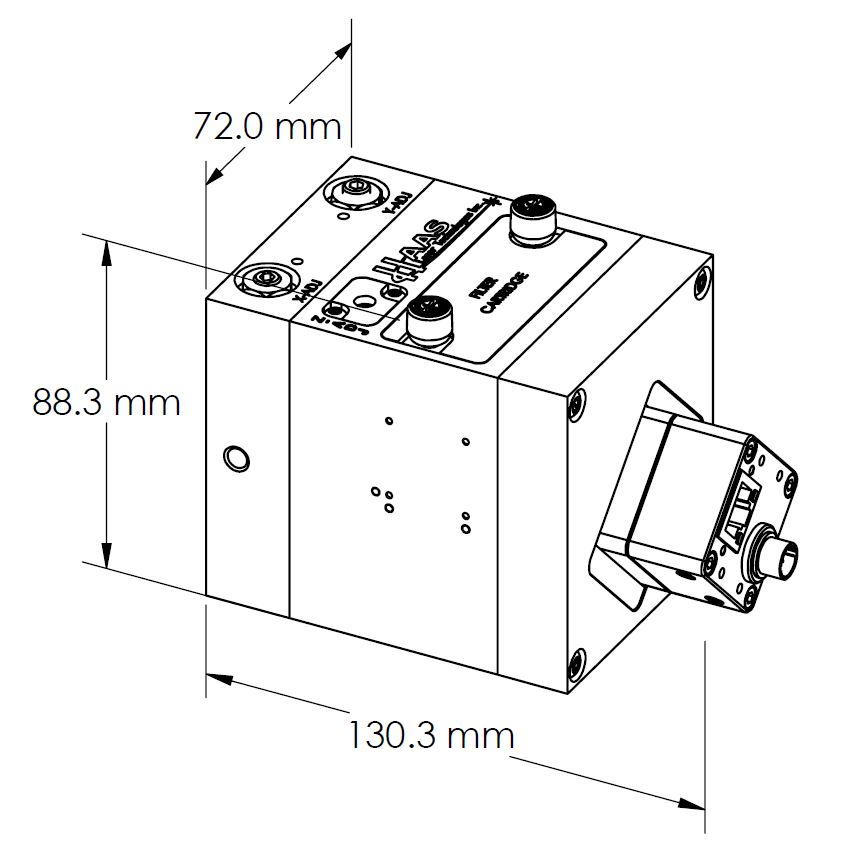

Smallest from factor for measuring real time M2Our system revolutionizes laser beam diagnostics with its unmatched compactness, blending seamlessly into various operational contexts:

With its focus on minimizing space requirements without compromising functionality, our system is engineered for efficiency, adaptability, and superior performance. |

|

|

BA-CAM The standard Beam Analyzer Camera capable of measuring an assortment of laser beam characteristics. |

BeamMapper TM The Additive Manufacturing configuration of the BA-CAM. Used for mapping the beam profile across a build volume. |

BA-CAM (High Power) High Power BA-CAM. Additional options for measuring laser powers up to 30 KW (500W option shown) |

|

BWA-CAM Beam Waist Analyzer Camera for measuring an assortment of laser beam waist characteristics. |

BWA-MON (Focused Input) BWA-CAM configuration for long focal length systems |

BWA-MON (Post-Focus Input) BWA-CAM configuration for measuring a laser system focal spot size and position |

|

BWA-MON (Collimated Input) BWA-CAM configuration for free space laser beam applications |

BWA-MON (Galvo Input) BWA-CAM configuration for additive manufacturing such as powder bed fusion |

BWA-MON (Fiber Input) BWA-CAM configuration for evaluating the fiber source. |

Not Sure Which Configuration is Right?Can’t figure out which camera or configurations are right for your application? Send us an email or give us a call, we are happy to help. |

ApplicationShop Profiling Cameras by application type. Configurations are available for Additive Manufacturing, cutting, welding or inspection. |

Additive Manufacturing (Laser Powder Bed Fusion)Using a Beam Waist Analyzer (BWA) in a Laser Additive Manufacturing (LAM) system offers several benefits, including:

|

"Novel Beam Diagnostics Improve Laser Additive Manufacturing "Explore the latest advancements in laser additive manufacturing (LAM) with our white paper, highlighting:

|

|

||

|

BA-CAM (High Power) High Power BA-CAM for measuring the beam profile at the origin. Additional options for up to 30 KW (500W option shown). |

BeamMapperTM Beam Mapper for measuring the beam profile anywhere in the build volume instantly |

BWA-MON (Galvo Input) Galvo Input BWA-MON for measuring real time M2 of a laser galvo system at the origin |

Not Sure Which Configuration is Right?Can’t figure out which camera or configurations are right for your application? Send us an email or give us a call, we are happy to help. |

Sign up for our

Quarterly Email Newsletter

Stay informed with laser industry news and new product releases

Check out our

Technical Center

Read white papers and articles, watch laser videos and learn more about optic design.

Haas Technical Center »

2.jpg)

.jpg)

-thumbnail.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

1.jpg)

.jpg)

.jpg)

.jpg)